The Process

We have identified six key milestones that custom workholding solutions go through. We offer these to share expectations and to help our customers plan for production and upcoming changes. All our custom solutions are a result of the collaboration with you. Your input on issues such as part configuration, material, tolerance requirement, and machining is the basis on which we build your solution. It all begins with a need, and then flows through the remaining steps:

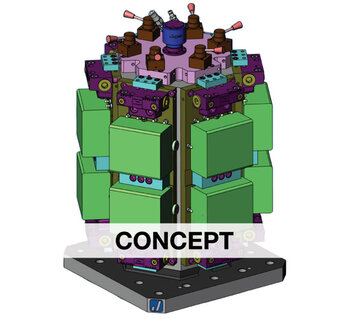

|

Step 1: Identify the Need

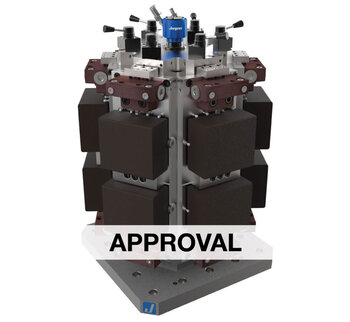

|

|

Take Your First Step!

The good news is you have a project, or the potential for a project, and you have considered the options for standard and custom workholding. We can help you with that decision, so Contact Us!