Machining Cast Part

| Previous Set-Up Method | Set-Up Using Ball Lock® System |

| Located part with dowel pins, bolted part to tombstone fixture. Indicated part to zero datum point. | Mounts parts to fixture plate while machining other parts. Mount fixture plate to tombstone using Ball Lock® Shanks. No indicating required because system provides +0.0005 (±0.013mm) repeatability. |

| Previous Set-Up Time: 15 minutes | Set-Up Time with Ball Lock® System: 60 seconds |

CNC Machine Base

Drilling and reaming forged part.

| Previous Set-Up Method | Set-Up Using Ball Lock® System |

| Fixture plate located with dowel pins bolted to machine base. Fixture plate and parts indicated. | Parts pre-mounted on fixture plate, which is then mounted to machine base using Ball Lock® Shanks. No need to indicate. |

| Previous Set-Up Time: 7 minutes | Set-Up Time with Ball Lock® System: 60 seconds |

CNC Vertical Machining Center

Machining aircraft valve parts.

| Previous Set-Up Method | Set-Up Using Ball Lock® System |

| New Project - New Machine - No Prior History | Using Ball Lock® Jigsaw Plate on Multi-Purpose Subplate enables operator to mount two more vises on the fixture. No indicating required. |

| Previous Set-Up Time: 12 minutes | Set-Up Time with Ball Lock® System: 45 seconds |

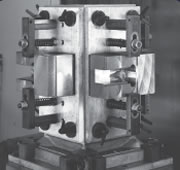

Two-Sided Tombstone

Drilling and tapping cylindrical bodies.

| Previous Set-Up Method | Set-Up Using Ball Lock® System |

| Fixture located and bolted to tombstone. Had to be indicated. | Fixture plate mounted and located with Ball Lock® Shanks. No need to indicate. |

| Previous Set-Up Time: 12 minutes | Set-Up Time with Ball Lock® System: 45 seconds |