Select a component to view all related products.

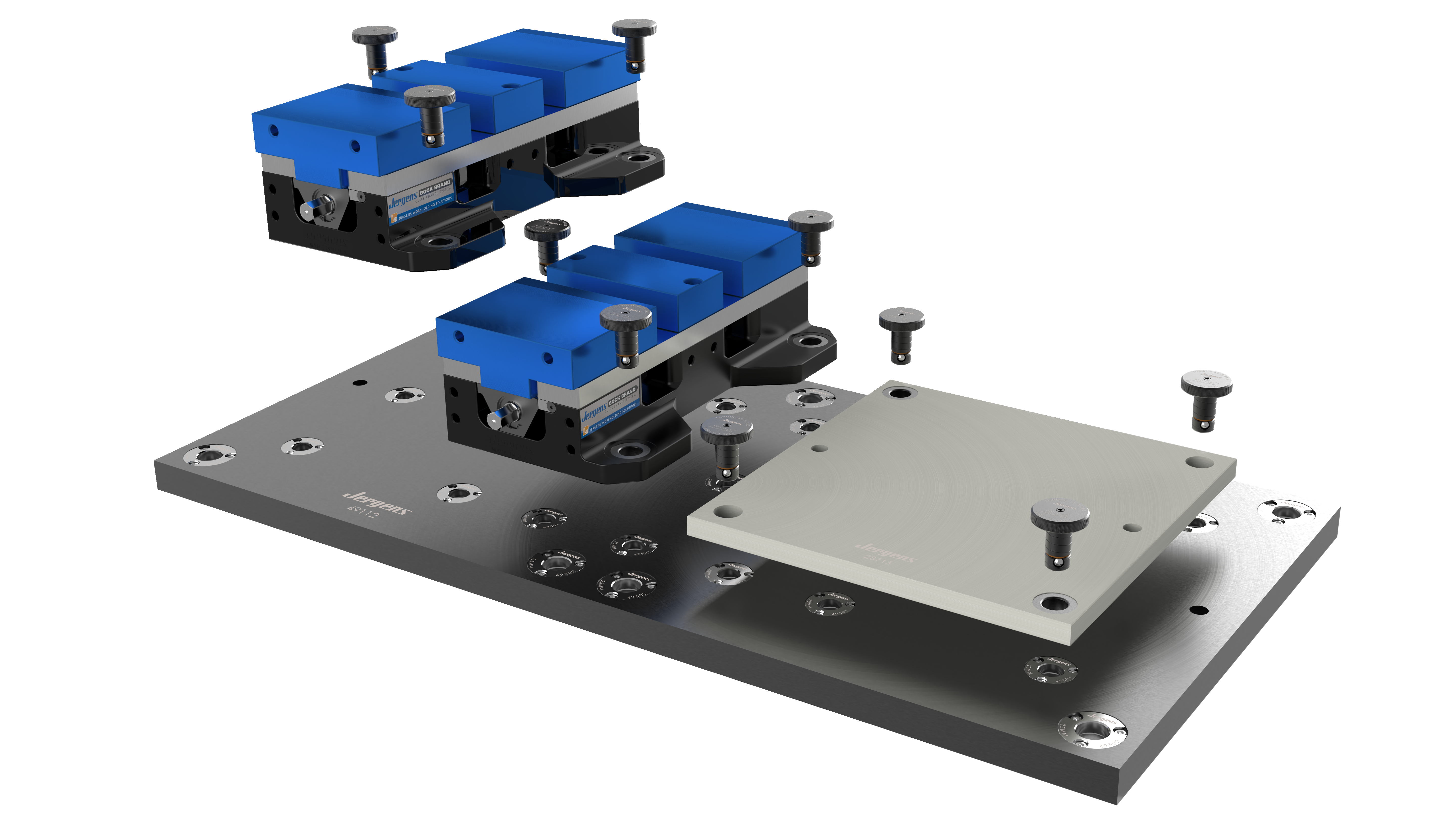

Any Ball Lock® application requires at least two sets of shanks, receiver bushings and liners. The liners are placed into the fixture plate to insure extremely accurate positioning. If more than two shanks are required (to provide additional hold down force), omit the liner bushing so that these additional holes will not interfere with your primary locating holes.

Locating repeatability will determine if one primary and one secondary or two primary liners are needed. With two primary liners, repeatability of ±.0005 inches can be maintained if the two holes for receiver bushings are held to a centerline distance of ±.0002 inch tolerance.

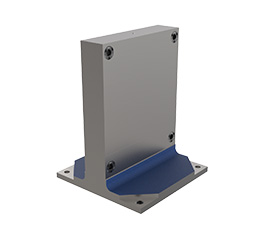

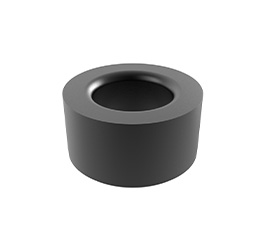

Two styles of receiver bushings are available. Generally, the face mount receiver bushing is utilized in blind hole applications (Slip Fit). The back mount receiver bushing is used in through hole applications (Light Press Fit). Note: Installed bushings should be approximately .012" (0.3mm) below subplate surface.

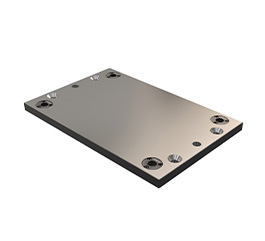

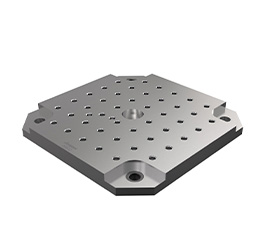

The Ball Lock® Mounting System is designed to speed the accurate locating and locking of fixture plates and subplates. Install a subplate wtih receiver bushings on your machine table.

The Ball Lock® Mounting System is designed to speed the accurate locating and locking of fixture plates and subplates. Add your fixture plate wtih two locating liner bushings. Additional Ball Lock® shanks are inserted through clearance holes in the fixture plate and set screws tightened for additional holding forced distributed across the fixture plate.