Easier Positioning And Clamping For Multiple Part Setups

Many machining operations benefit from multiple part setups, right? Maximize machine uptime, capacity and capability. Size, shape and complexity of surfaces to be machined usually dictate what’s possible. So does the total machining envelope that the CNC will allow. Jergens has an answer to how to best position and clamp the highest number of parts while staying clear of tool paths and spindle movements – sound OK?

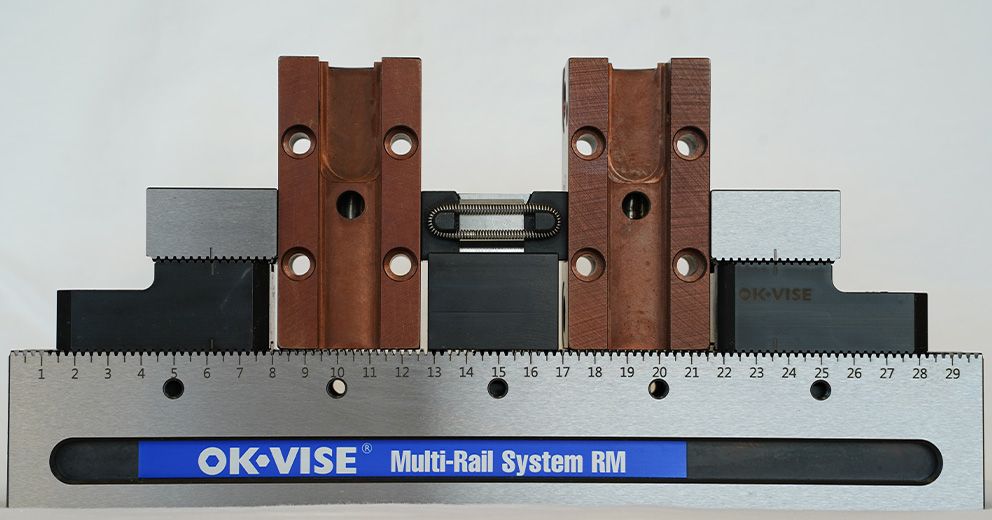

Watch Your Machining Take Off On A Rail

It is, OK-Vise®, Jergens low profile modular clamping system that uses the RM Multi-Rail and clamping modules to hold tight and stay out of the way. General-purpose and totally customizable, Multi-Rail and the other OK-Vise® system components, make it possible, even easy, to configure your workholding exactly to your need in order to optimize machining. We’ve recently added a number of fixture set components for even greater ease of use and capability, including Parallels and Side Guides for positioning, as well as Clamp and Stop Modules to hold workpieces securely during machining.

Getting Positioned For Productivity, Quickly

T Slot, magnetic and Snap-in Parallels assist in the positioning of a workpiece on the RM rail, avoiding contact with the serrations through a raised datum surface. Mechanical and magnetic Side Guides also assist in positioning the workpiece. They are mounted either to the tapped holes in the side of the rail or via the strong magnet for a wide range adjustment and the ability to move rapidly from one location to another. You can adjust each side guide for a specific product while keeping the guide ready for the next production batch.

Clamped In And Held Tight

Holding workpieces securely with OK-Vise® is done with Clamp and Stop Modules. In addition to our full line, we have added new B and D Series Clamp Modules that feature a standard clamp combined with a riser plate (B Series), socket head cap screw, and t-nut, as well as a choice of jaw faces – smooth, serrated, mixed and mounting jaw. Stop Modules hold fast against clamping pressure and are also available in several styles including smooth, serrated, knife, V-stops – both vertical and horizontal – and more.

In total, this system provides near-endless fixture configurations, consistent holding and machining of challenging workpieces both large and small including multiples clamped simultaneously, and the ability to mount to the Jergens Quick Locating (QLS) Grid System for next-level productivity.

For more information on the new OK-Vise® additions, or any of our complete line of workholding solutions, don't hesitate to contact us.

For more products and information, check out our OK-Vise® brochure.