Cycle Time Reduction – Better Workholding Just Got Even Easier

If you’re machining multiple parts simultaneously on your CNCs with frequent changeover, you well know the importance of quick and accurate location. Shortened overall cycle times can mean the difference between profit and loss. Jergens Zero Point System provides this key advantage and has now been expanded to include new pneumatic subplates and multi-pull stud fixture plates to further optimize the choice for workholding.

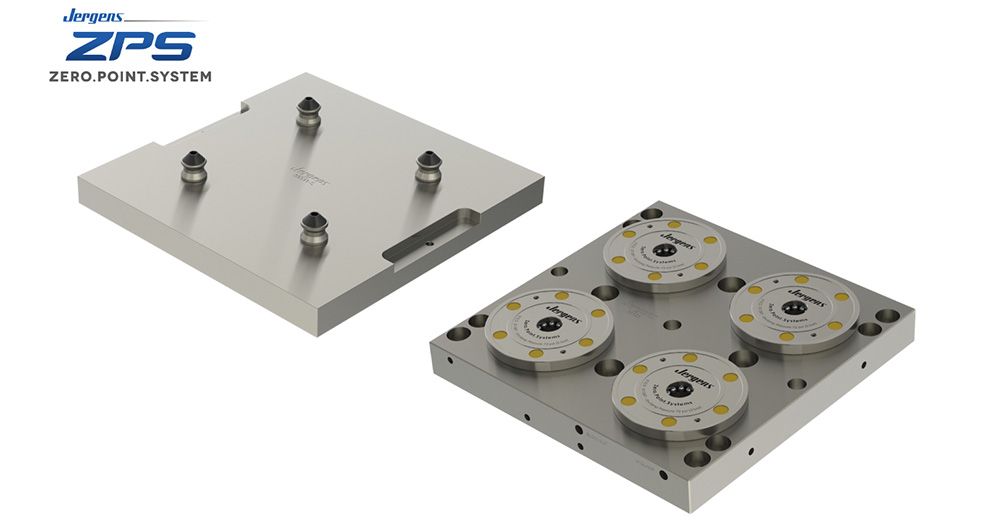

ZPS Efficiency For Two-Place and Four-Place Setups

Six new pneumatic subplates, each featuring pre-installed low pressure pneumatic clamping modules, offer a variety of configurations to suit the need. Three 2-module units and three 4-module units. The pneumatic subplates are constructed of Fremax 15 Steel (or equivalent) for durability and long life and include quick connects for changeover speed as well as porting for blowout in between machining cycles. System repeatability is less than 0.005 mm (0.0002 in).

Additionally, Jergens ZPS now includes fixture plates (aluminum or steel) with pre-installed pull-studs as a convenient step forward. A two-stud model is suitable for two ZPS modules and includes one ZPS stud and one timing stud, and the four-stud model for four ZPS modules includes ZPS and timing studs plus two additional clearance studs. Custom sizes are also available to suit specific needs.

Fix, position and clamp in a single step. Sounds pretty easy, right?

It is, but it only works if you have an exact setup like ZPS, a unique solution that allows customers to do all three in a single step with one important goal in mind – reduce part changeover time with no loss in accuracy. This Jergens exclusive reduces set-up time by as much as 90% and is offered in a variety of fixture plates, subplates, clamping modules and other accessories as well as kits.