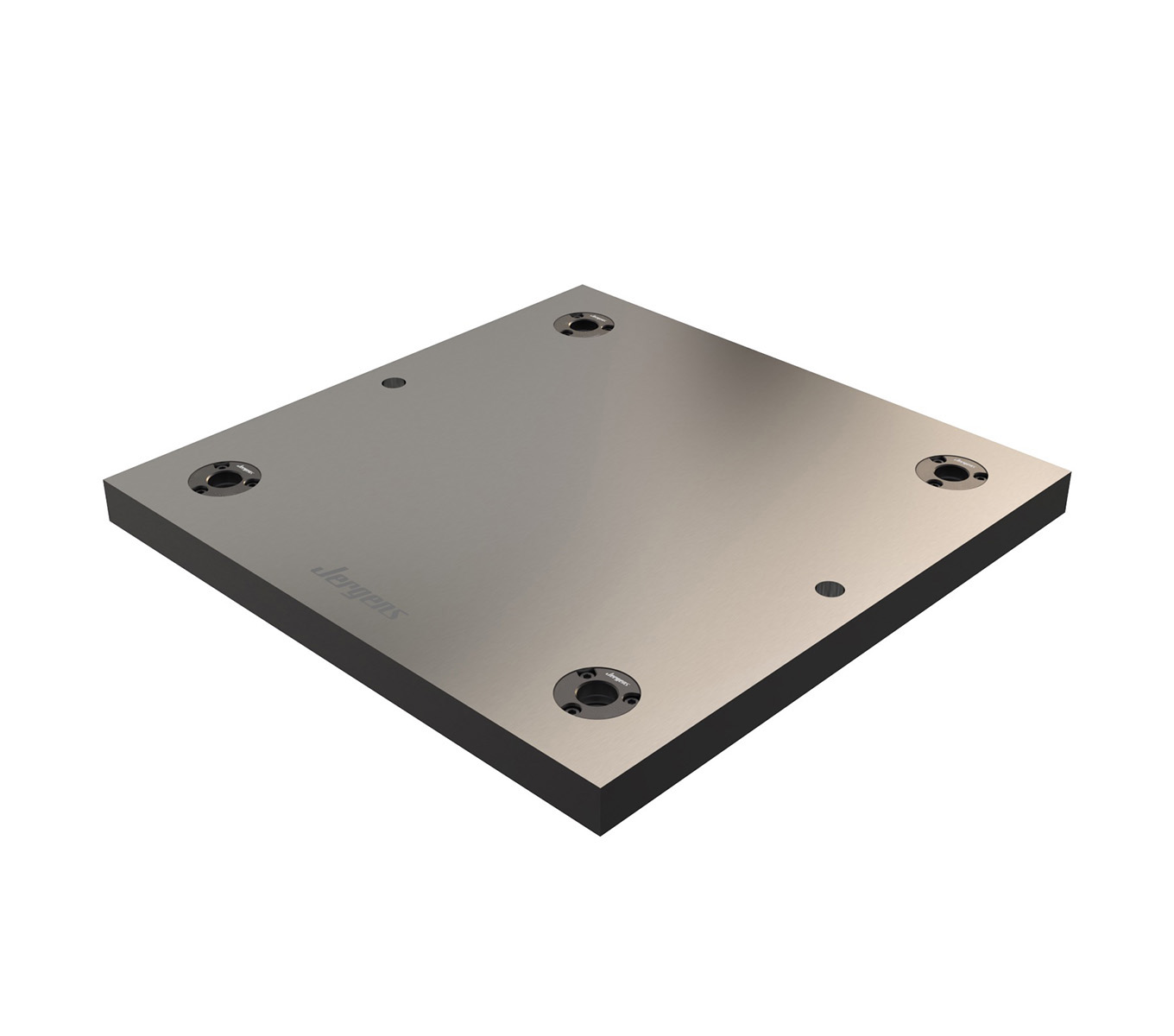

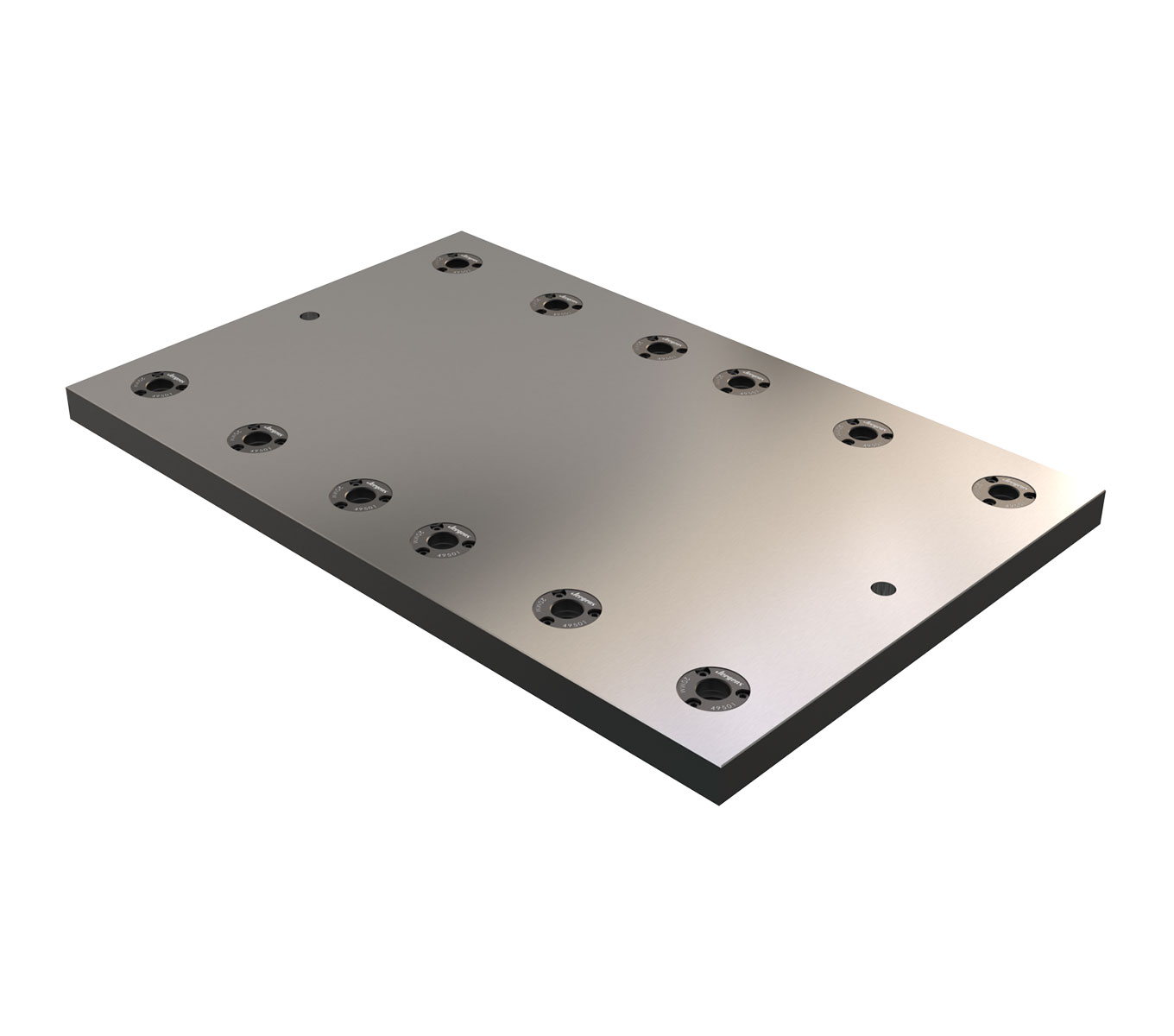

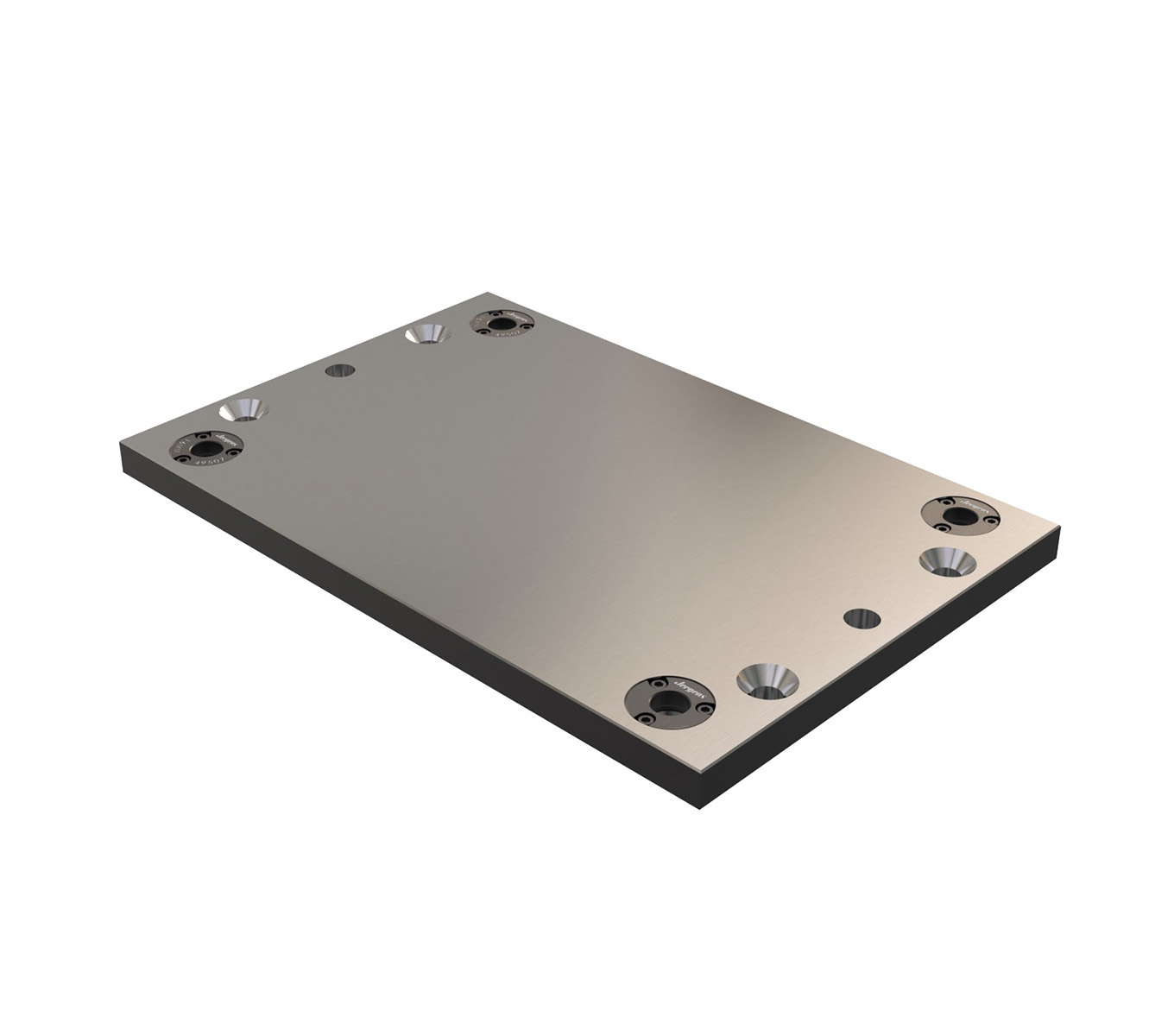

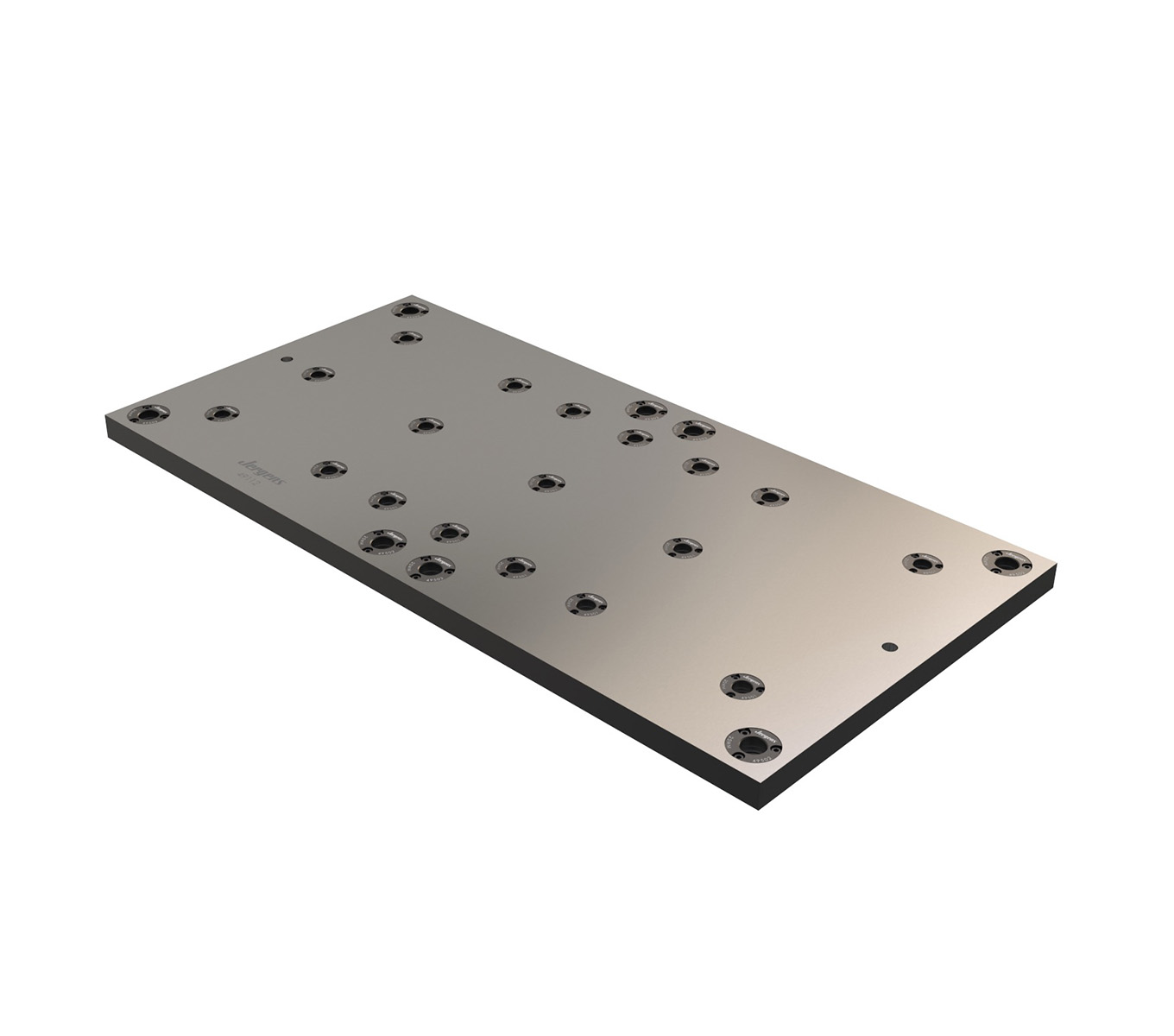

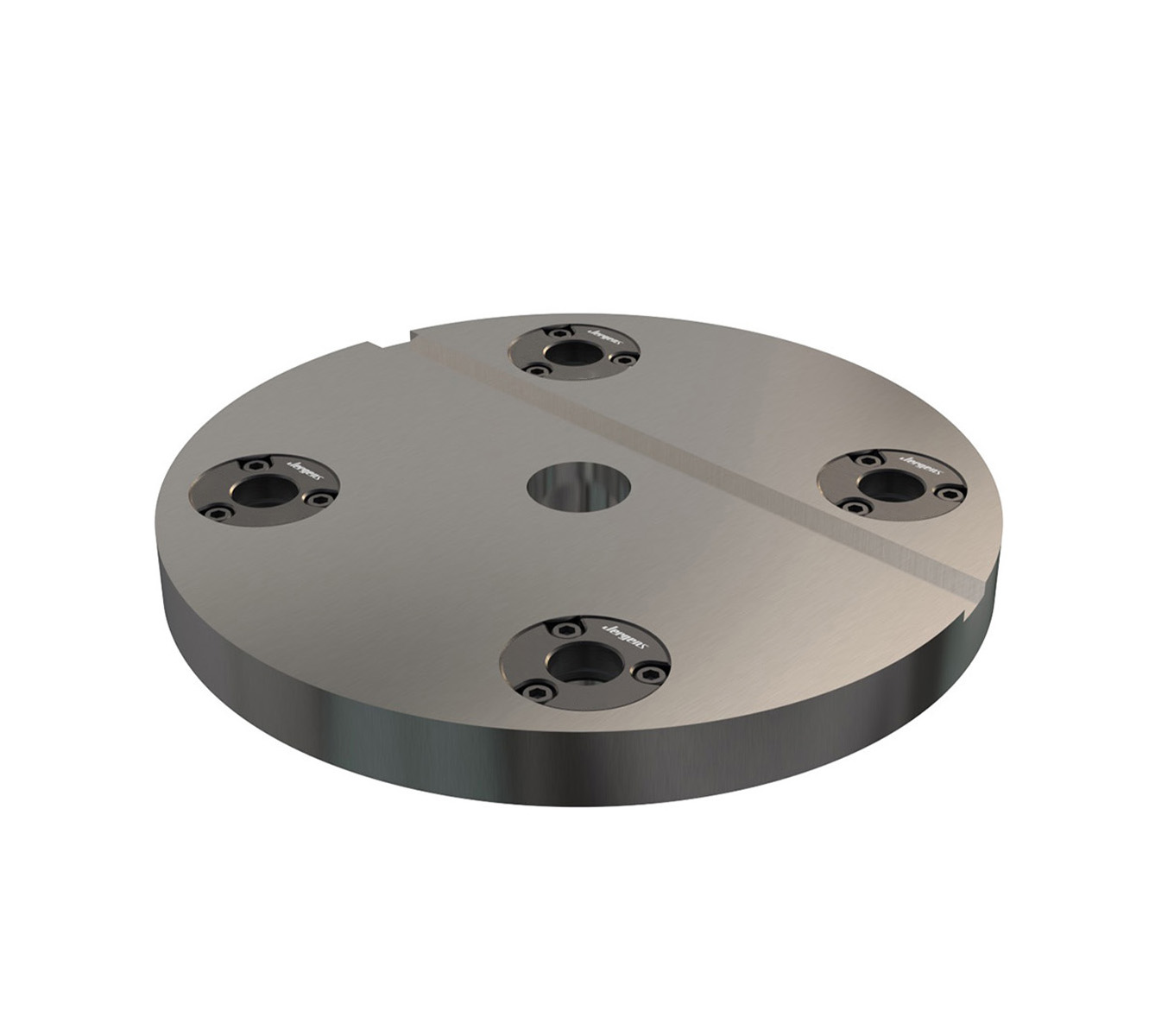

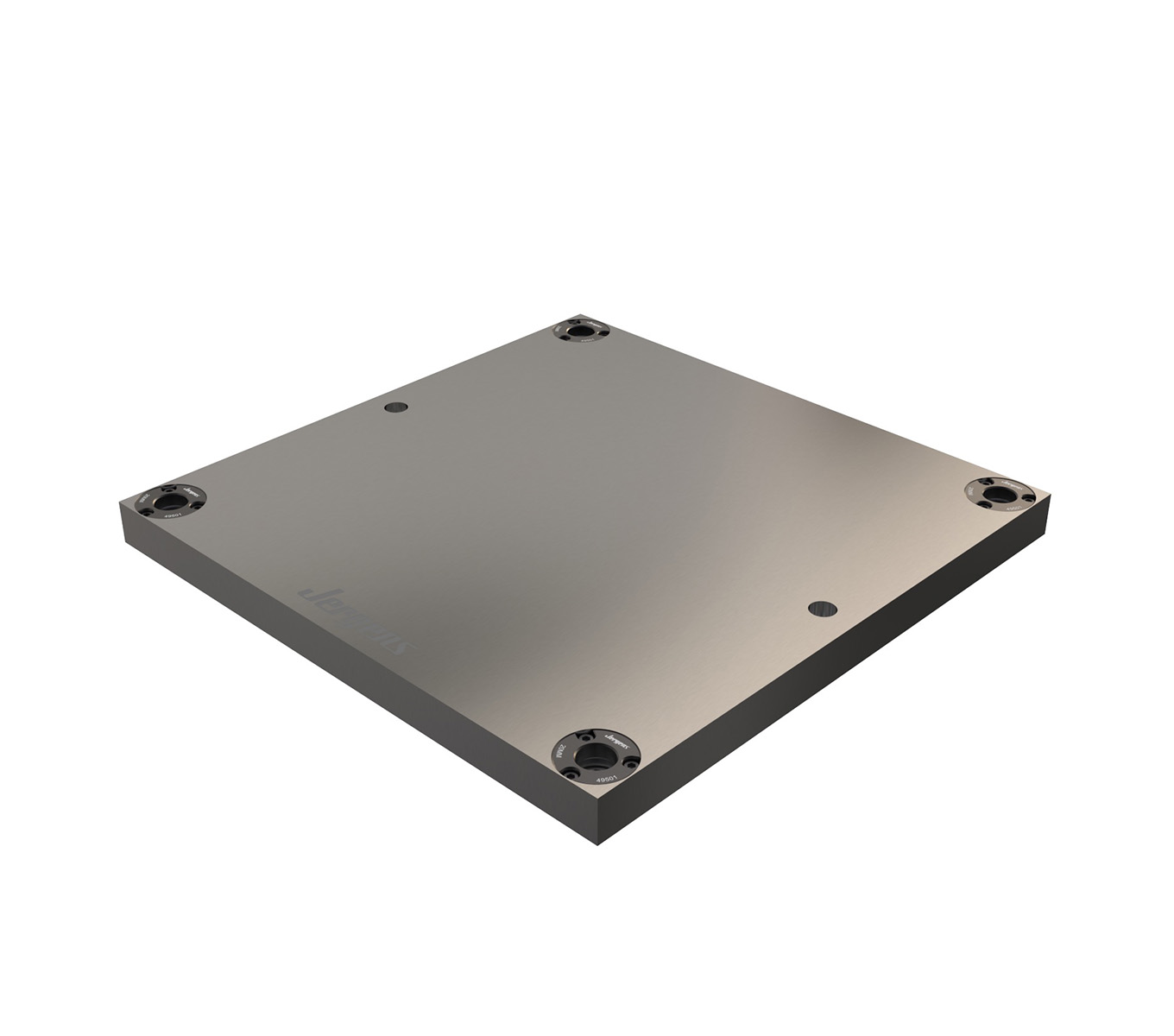

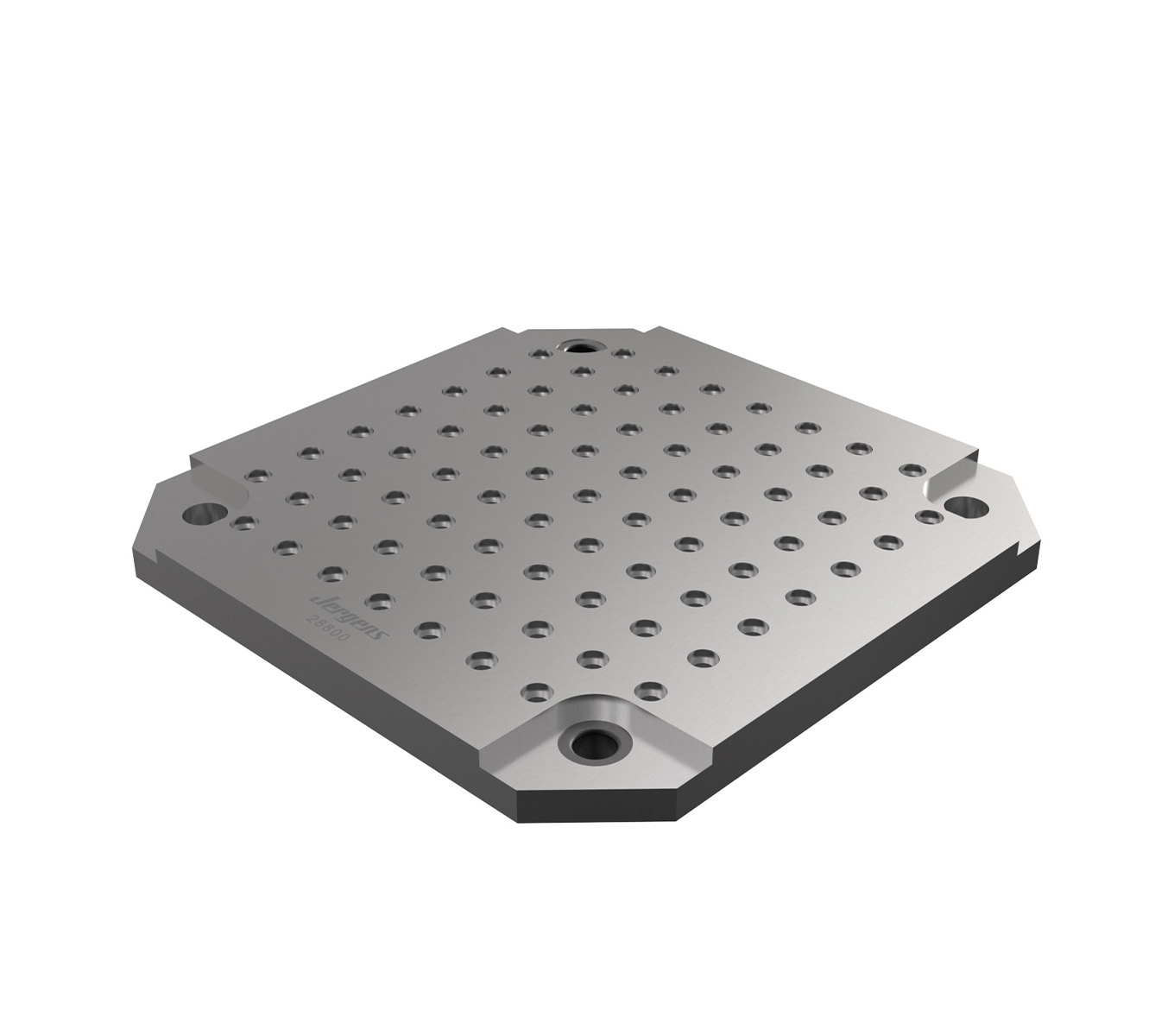

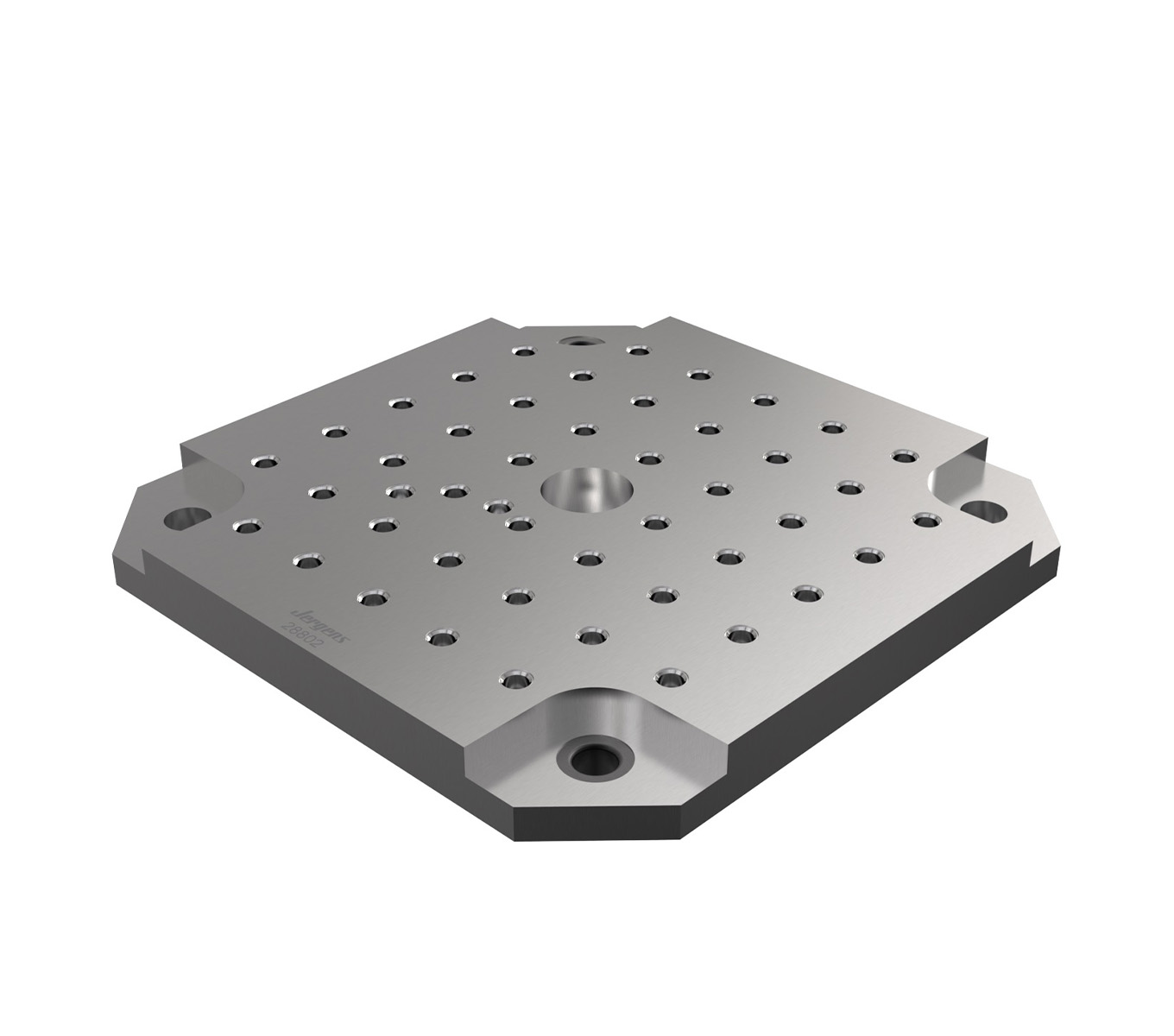

Ball Lock® Fixture Plate Machining Kit

Ball Lock® Fixture Plate Machining Kit allows a fixture plate to be installed on a subplate with clearance between the plates. When a user is initially building a fixture on a Ball Lock® Fixture Plate, this clearance allows cutting tools to break thru the fixture plate without damaging the subplate below. The advantage of this setup is fixture plates can be machined while mounted to the same subplates they will use within production.

Features, Benefits, & Product Specifications:

-

Each kit includes (4) Ball Lock® Shanks and (4) Spacers

-

Additional Ball Lock® Shanks and Spacers can be purchased separately

Ball Lock® Fixture Plate Machining Kit

Select a part number for CAD drawings, price and stock availability.

| Part Number | CAD | Unit | Shank Diameter (mm) | Spacer Diameter A (In) | Spacer Thickness B (In) | Fixture Plate Thickness C (In) | Shank Head Thickness D (In) | Shank Head Diameter E (In) | Shank Part Number | Spacer Part Number |

|---|---|---|---|---|---|---|---|---|---|---|

| 49242 |

|

Inch | 20 | 2.00 | 0.50 | 1.00 | 0.38 | 1.75 | 49603 | 49582 |

| 49243 |

|

Inch | 20 | 2.00 | 0.75 | 0.75 | 0.38 | 1.75 | 49603 | 49583 |

| 49244 |

|

Inch | 13 | 1.625 | 0.50 | 0.75 | 0.25 | 0.87 | 49604 | 49584 |

| 49249 |

|

Inch | 16 | 1.75 | 0.50 | 0.75 | 0.32 | 1.50 | 49609 | 49589 |

| 49253 |

|

Inch | 25 | 2.375 | 0.50 | 1.00 | 0.38 | 2.00 | 49613 | 49593 |

Documents and Videos

Operating Manual

Operating Manual - 81600 ONLY

Jergens Production Vise System

Jergens Production Vises Features and Benefits

Vertical Machine Solutions

Horizontal Machine Solutions

Hydraulic Production Vises

Production Vises