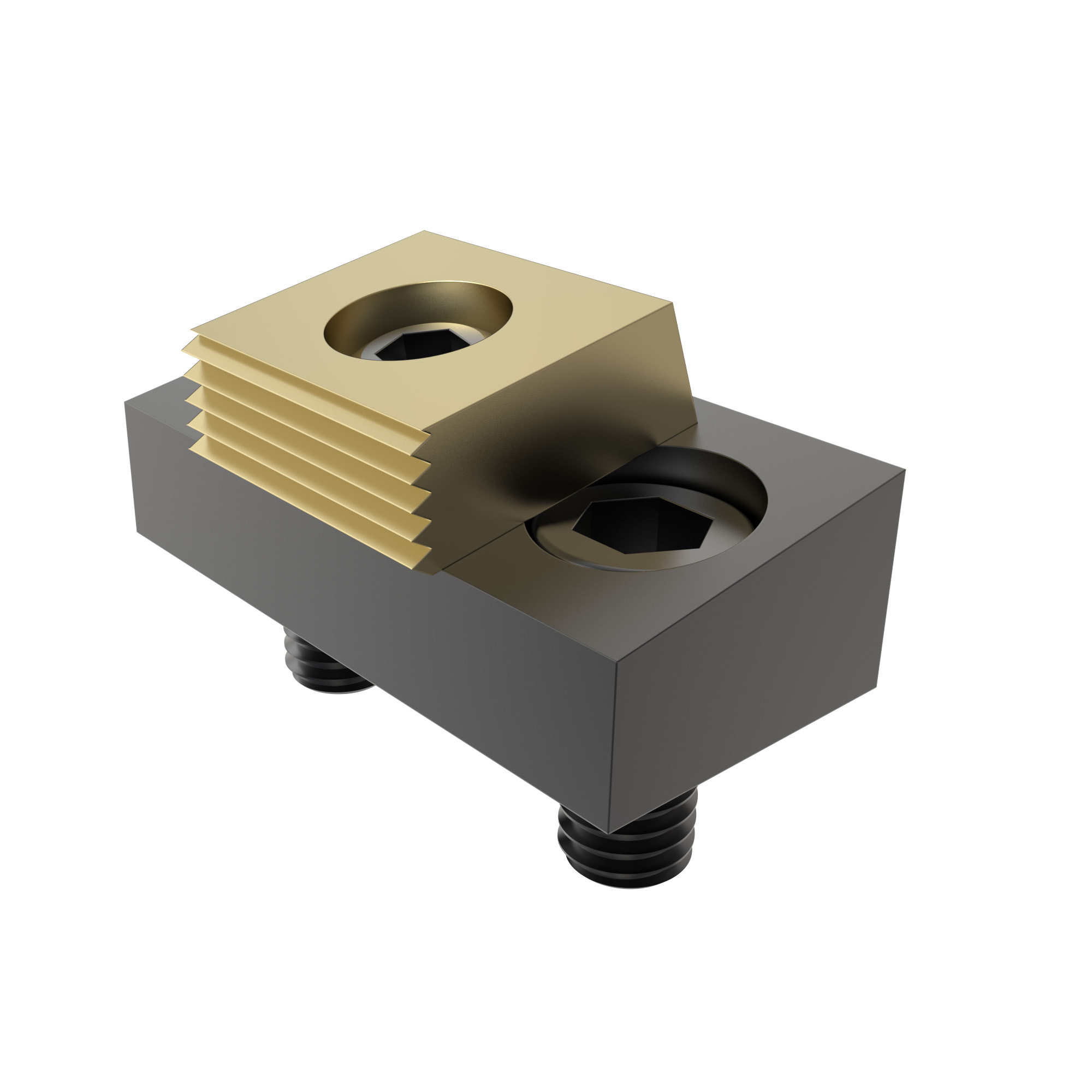

Micro™ Toe Clamps

Jergens Micro™ Toe Clamps provide positive down force while using very little space on the fixture. Workpieces can be clamped in series by using the back surface of a clamp to locate the next workpiece. The hardened steel clamping element has both a smooth surface for machined workpieces and a serrated clamping surface for rougher work. The height of the clamp can be adjusted by milling the slot deeper in the fixture plate.

Features, Benefits, & Product Specifications:

-

More efficient usage of machinable area

-

Reduction in the number of tool changes

-

Extended cycle times

-

Free tool access to the workpiece

-

Less space is required compared to traditional vises

-

Overall time savings

Note(s):

-

The “E” dimension is the distance needed between the front of the clamp base and the workpiece.

Micro™ Toe Clamps

Select a part number for CAD drawings, price and stock availability.

| Part Number | CAD | Unit | A (In) | B (In) | C (In) | D (In) | E (In) | F (In) | G (In) | H (In) | I (In) | Cam Screw Part Number | Distance of Movement (In) | Mounting Screws | Torque (ft/lbs) | Holding Force (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 68731 |

|

Inch | 1.70 | 0.75 | 0.50 | 1.00 | 0.090 | 0.75 | 0.25 | 0.62 | 0.845 | 68999 | 0.050 | 5/16-18 x 3/4 LH | 20.8 | 2000 |

| 68732 |

|

Inch | 2.12 | 1.00 | 0.45 | 1.32 | 0.110 | 1.00 | 0.38 | 0.62 | 0.960 | 68201 | 0.100 | 3/8-16 x 3/4 LH | 65.0 | 4000 |

| 68733 |

|

Inch | 2.95 | 1.50 | 0.99 | 2.00 | 0.130 | 1.50 | 0.50 | 1.25 | 1.70 | 68203 | 0.100 | 1/2-13 x 1 1/4 SHCS | 100.0 | 6000 |

| Part Number | CAD | Unit | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | Cam Screw | Distance of Movement (mm) | Mounting Screws | Torque (Nm) | Holding Force (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 68781 |

|

Metric | 43.2 | 19.0 | 12.7 | 25.4 | 2.3 | 19.0 | 6.4 | 15.75 | M10 | 1.6 | M8 | 28.0 | 8900 |

| 68782 |

|

Metric | 54.0 | 25.4 | 11.4 | 33.5 | 2.8 | 25.4 | 9.7 | 15.75 | M12 | 2.0 | M10 | 88.0 | 17800 |

Documents and Videos

Operating Manual

Operating Manual - 81600 ONLY

Jergens Production Vise System

Jergens Production Vises Features and Benefits

Vertical Machine Solutions

Horizontal Machine Solutions

Hydraulic Production Vises

Production Vises