Jergens Inc. To Display Machine Tending Solutions at Automate 2024 at Booth #5482 McCormick Place, Chicago.

Mar 26, 2024

Jergens will present its growing workholding automaton components for unmanned and lights out manufacturing applications.

Jergens Inc. To Display Machine Tending Solutions at Automate 2024 at Booth #5482 McCormick Place, Chicago.

Mar 26, 2024

Jergens will present its growing workholding automaton components for unmanned and lights out manufacturing applications.

Getting a Grip on Lights-Out Machining

Dec 08, 2023

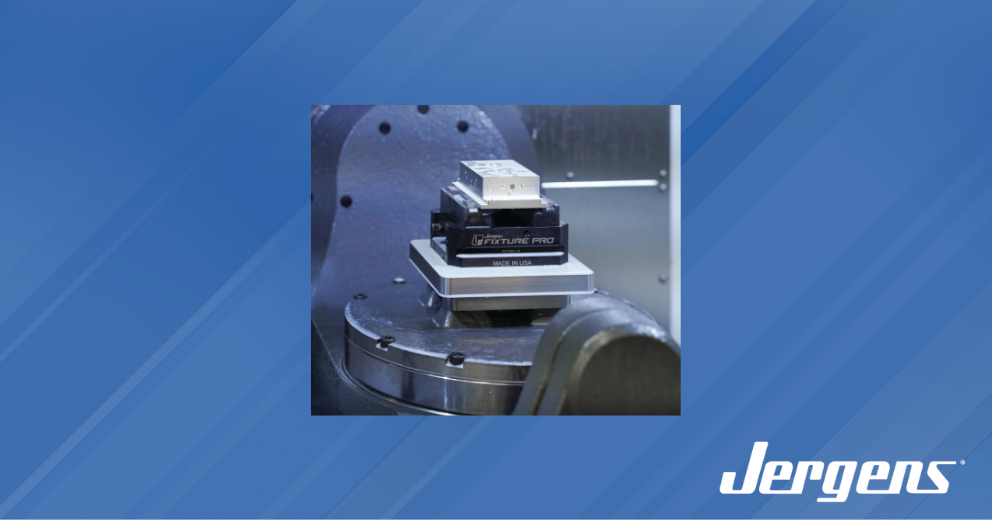

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

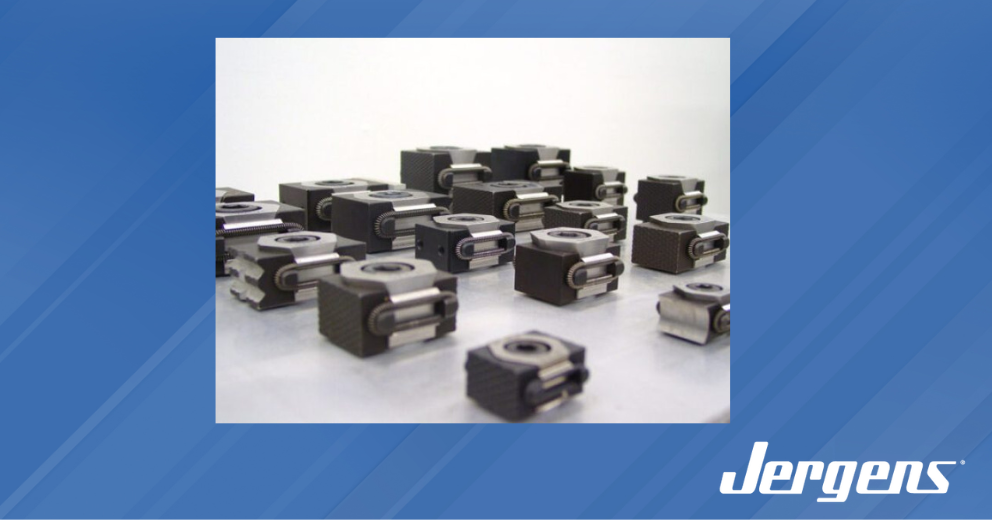

What Is a Low-Profile Clamp and How To Utilize It In Your Production

Nov 22, 2023

In our latest blog post, we are diving into the subject of what a low-profile clamp is and how to utilize it in production. It will help you gain better understanding of low profile clamps and their usage.

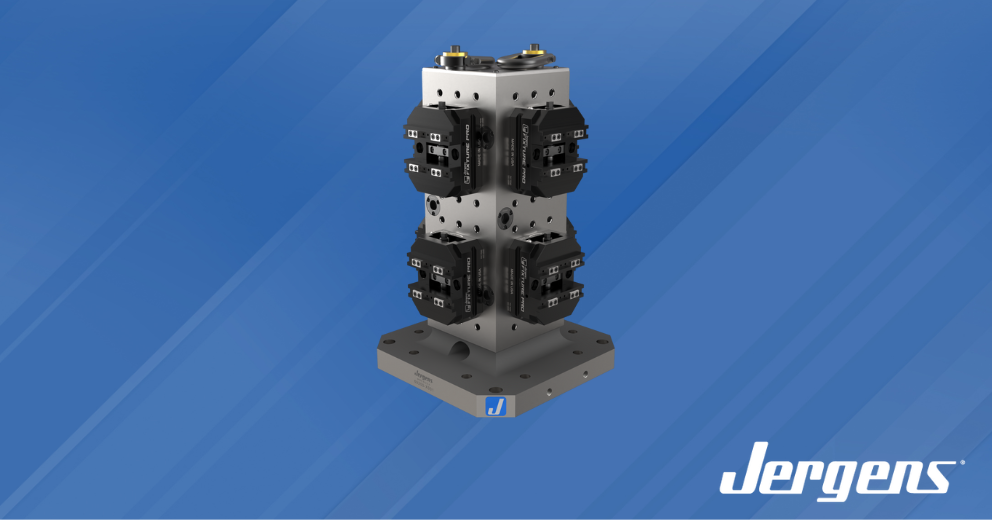

Getting The Most Out of Your HMC - Five Workholding Musts

Sep 29, 2023

Finding the sweet spot for your shop’s productivity is very much a human effort, and a matter of choosing the best combination of man and machine. In the case of high producers like HMCs, the goal continues to be loading and changing parts faster than the machine can make them.

Jergens Inc, a Company Known for Its Quick-Change Workholding Innovations and Custom Solutions

Jul 28, 2023

Jergens continues its developments including Cast Iron Tooling Columns, 5-Inch Heavy-Duty Vises, Quick-Loc™ 2 Pallet Systems, ZPS Modules, and a (Machine) Washdown Tool.

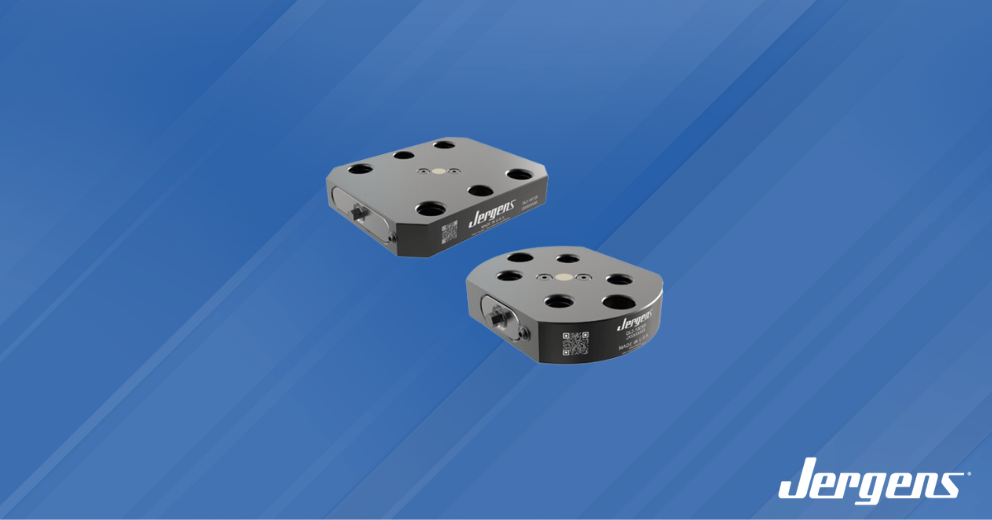

Jergens Inc, New Quick-Loc™ 2 Modular Pallet System Provides Multiple Top Tooling Mounting Options For Multi-Axis Machining

May 23, 2023

Jergens new Quick-Loc™ 2 Pallet system provides quick change for multiple parts even with different top tool setups.