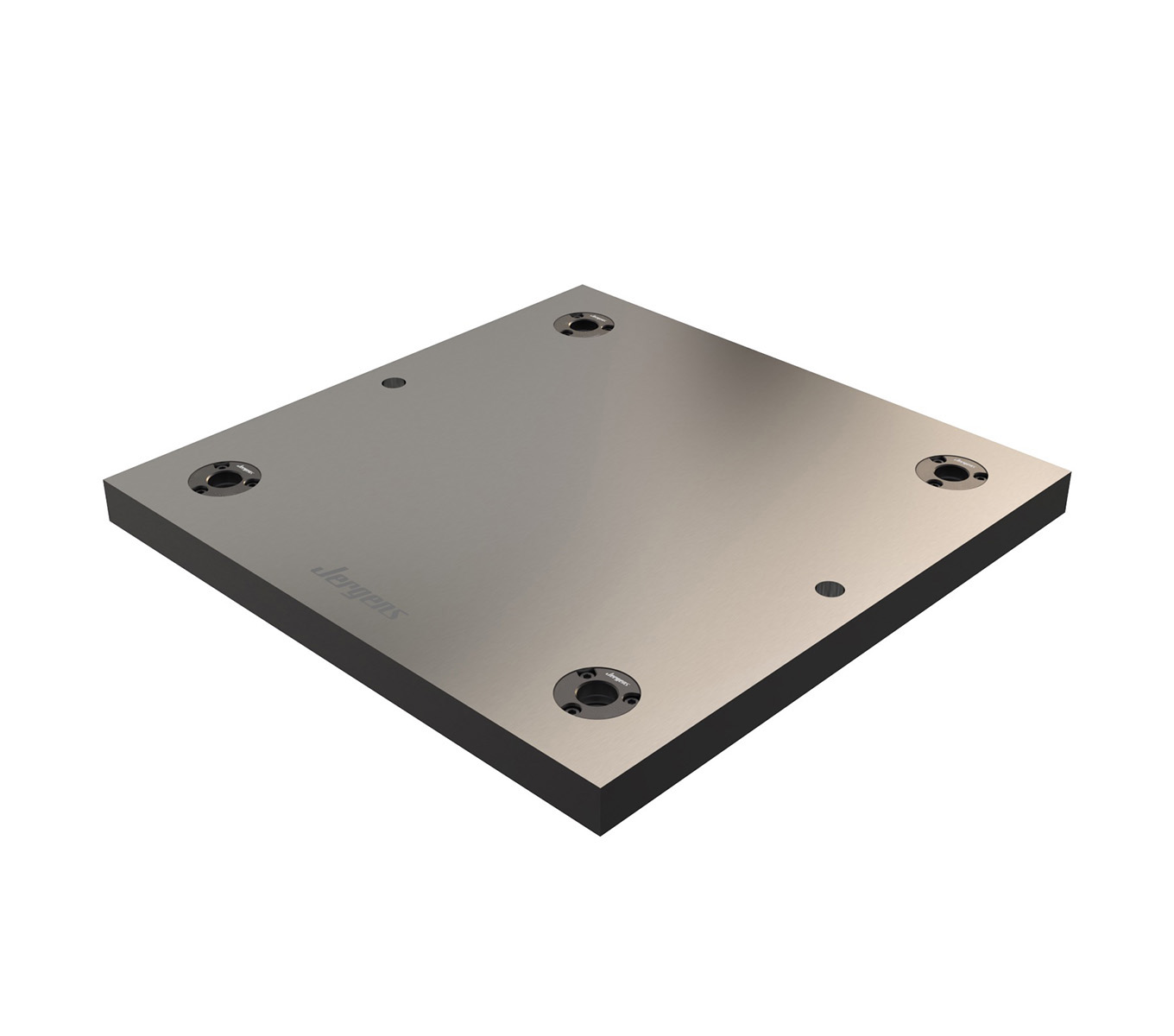

Ball Lock® Quick Change Kits

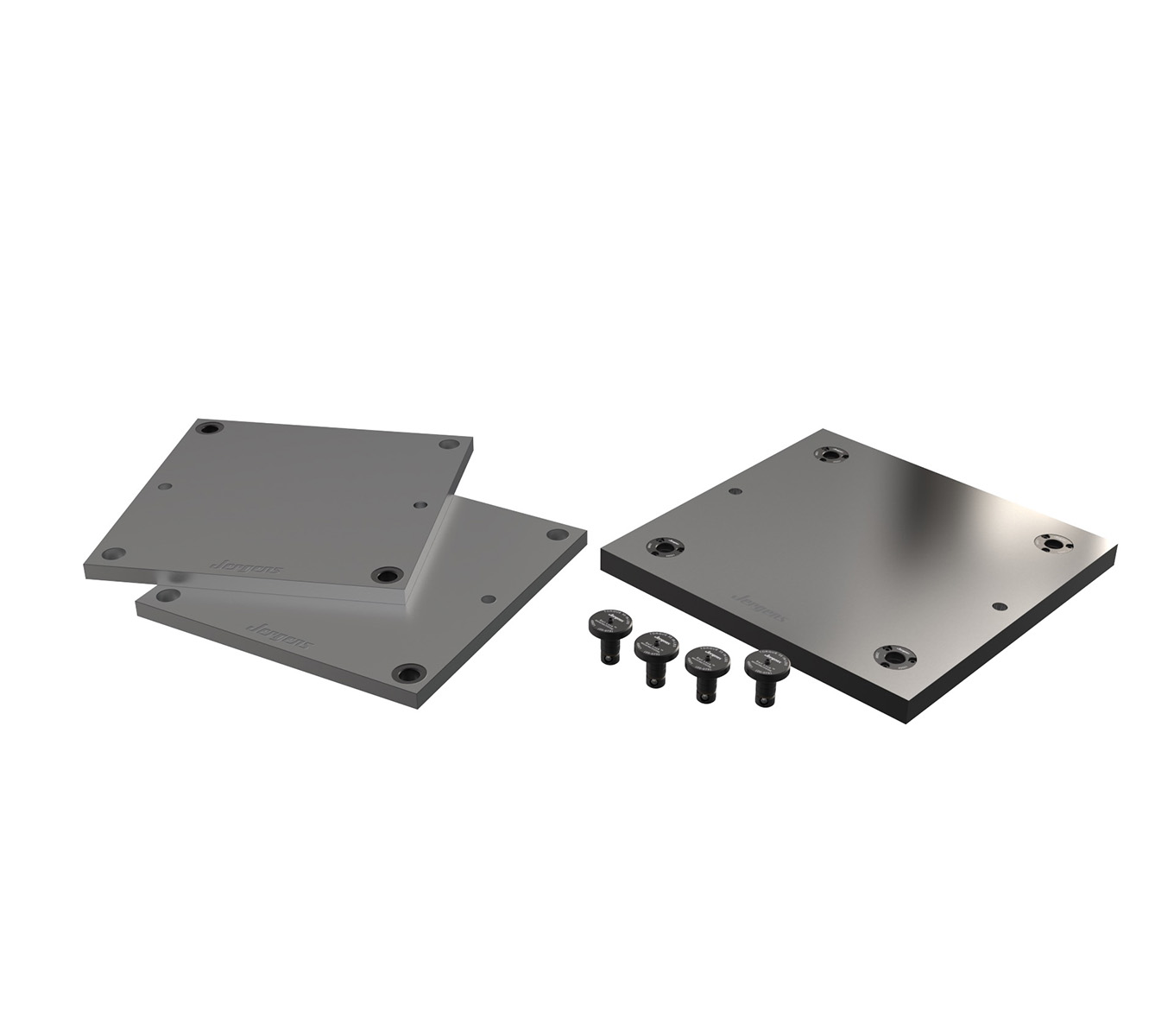

Jergens Ball Lock® Quick Change Kits speed fixture changeover in all types of manufacturing operations. While one fixture plate is on the machine, the operator can load parts on the other. This minimizes downtime for true set-up reduction.

To enable the subplate to be mounted on a slotted table without the need to indicate the subplate, sine fixture keys can be used. The sine fixture key bored holes are oriented parallel to the receiver bushings on the subplate and to the liner bushings on the fixture plate. These also allow the fixture plate to be mounted on a toolroom mill without the need to indicate it. This is extremely useful when machining location points on your fixture.

Each Quick Change Kit includes:

-

(2) Aluminum Ball Lock® Fixture Plates with (2) Primary Liner Bushings installed

-

(1) Steel Ball Lock® Standard Subplate with (4) Receiver Bushings installed

Ball Lock® Quick Change Kits

Select a part number for CAD drawings, price and stock availability.

| Part Number | CAD | Unit | Fixture Plates | Fixture Plate Part Number | Subplates | Subplate Part Number | Ball Lock Shank | Ball Lock Shank Part Number |

|---|---|---|---|---|---|---|---|---|

| 49001 | Inch | 14"x14"x3/4" (2) | 28713 | 16"x16"x1-1/8" (1) | 49101 | 20mm (4) | 49601 | |

| 49002 | Inch | 16"x16"x3/4" (2) | 28715 | 16"x16"x1-1/8" (1) | 49101 | 20mm (4) | 49601 | |

| 49004 | Inch | 10"x15"x3/4" Bridgeport-Style (2) | 28731 | 10"x15"x3/4" (1) | 49121 | 16mm (4) | 49608 | |

| 59002 |

| Part Number | CAD | Unit | Fixture Plates | Fixture Plate Part Number | Subplates | Subplate Part Number | Ball Lock Shank | Ball Lock Shank Part Number |

|---|---|---|---|---|---|---|---|---|

| 59002 | Metric | 400 X 40 X 20mm (2) | 58715 | 400 X 40 X 25mm (1) | 59101 | 20mm (4) | 49651 |

Documents and Videos

Operating Manual

Operating Manual - 81600 ONLY

Jergens Production Vise System

Jergens Production Vises Features and Benefits

Vertical Machine Solutions

Horizontal Machine Solutions

Hydraulic Production Vises

Production Vises